What's a Boilermaker? We're the skilled craftsmen and women trained and committed to stand apart as the best in rigging, welding and other specialty crafts. We step up when others step back, completing the jobs others are afraid to begin. We solve the hardest problems. And we're the choice for owners and contractors who want the job done right—on time, within budget and safely. Every time.

We're a brotherhood. And everything we are begins with our bond. That's our advantage.

Let's get to work together.

Our Work

-

Refinery

We know refineries. Our RSO-trained, ASME-coded Boilermakers are ready to work on your next refinery project. We can weld in tight spaces. We can rig anything. Our work in refineries shows we perform turnarounds safely and on time, as we did for PBF.

PBF Energy refinery in Torrance, California, needed an overhaul and update of its facility. It hadn't been through a turnaround in 25 years. PBF called the Boilermakers to get the job done right.

“The star partner in this project was the Boilermakers. I truly believe the Boilermakers are setting a standard that, if followed by the other craft unions, will allow the building trades to become the labor of choice throughout North America.

–PBF Senior Vice President of Refining Herman Seedorf

-

Nuclear

For generations, Boilermakers have been working in nuclear power plants. We're ASME-coded to perform all types of pressure welding. We're safety-conscious, multi-skilled welders, riggers, fitters and more. We finish jobs injury-free and on time, as we recently did for Southern Nuclear.

Southern Nuclear Company praised the Boilermakers' work at Plant Vogtle Units 3 & 4 in southeast Georgia. Union crafts completed 53 million man-hours without lost-time injury. Boilermakers were part of the 6,000 union craft workers on site.

“For any construction project, especially a complex and demanding one like ours, this milestone is worthy of celebrating. We continue to add safe work hours and improve upon our safety culture with each passing week, illustrating that zero injuries is possible.

— Southern Nuclear Company CEO and President Steve Kuczynski

-

Renewables

Boilermakers believe in inclusive energy solutions to climate change, and our work shows that. Our multi-skilled welders, riggers and fitters build hydro, solar, biomass and other renewable projects, such as Ivanpah's solar thermal facility.

Boilermakers constructed the $2.2 billion, 392-MW Ivanpah solar thermal project. Developed by BrightSource Energy, the facility provides power to PG&E and Southern California Edison. Each of the project's three 459-foot towers supports a boiler. Boilermakers constructed the boilers and erected the water storage tanks and air-cooled condenser units that recover water from spent steam. Weld acceptance rates have been impressive: 99.5 percent on unit 1 and 100 percent on units 2 and 3.

““If you think about the challenges that we've done here, we've met them all. And we certainly couldn't have done it without the Boilermakers that we've had here. It's the quality of the Boilermakers we've got here. I've told this to many people. I've been with Bechtel almost 30 years and I have to say that this is the best team that I've ever worked with.

— Site Manager, Bechtel Power Corporation, Fred Fine

-

Power Generation

Boilermakers have a diverse portfolio of work within power generation, including projects in gas-fired, biomass, nuclear and coal-fired power plants. Our productive, multi-skilled craftsmen can weld, fit and rig anything, anywhere and in any season, as we did for TVA.

In the spring of 2017, Tennessee Valley Authority had 56 projects across 10 planned outages with a $15.9 million investment in TVA's Kingston Project. Boilermakers manned those outages. During the four months of work, there were zero safety incidents, zero environmental incidents, and no clearance violations, workplace conduct issues or quality issues. In addition, TVA met or beat every outage schedule, met their budget and maintained exceptional housekeeping.

“I've worked on a lot of coal plants and worked with a lot of Boilermakers for a long time on back-end jobs...You've got so much work in a small area, and the Boilermakers are the first ones out of the gate...The Boilermakers performance and expertise on these jobs is more critical than ever.

— Tennessee Valley Authority, Billy Ours, project manager, Kiewit Power

Boilermaker Facts

- The Boilermaker lost-time rate has consistently beaten the national average for the construction industry — .6% in 2018 compared to Boilermakers' .12%

- The Boilermaker substance abuse testing program became mandatory in 1996, making the Boilermakers the ONLY building trades union to impose it as a requirement.

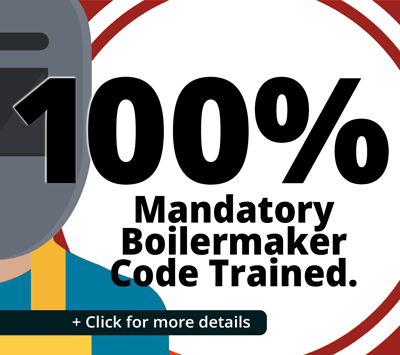

- All construction Boilermakers are required to complete Boilermaker Code training, a program designed to create a cultural shift and provide employers with a reliable, skilled workforce.

- Through rigorous training, Boilermakers have lowered OSHA recordable injuries by 90% since 1989.

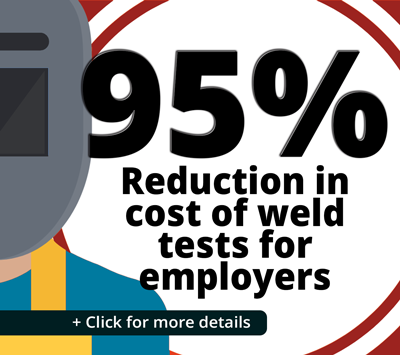

- The Boilermakers' Common Arc Program has resulted in a 95% drop in welding certification costs to owners and contractors.

- The Boilermakers Delivery System is a proprietary system that connects Boilermakers, owners and contractors with real-time availability, project opportunities and manpower demand.

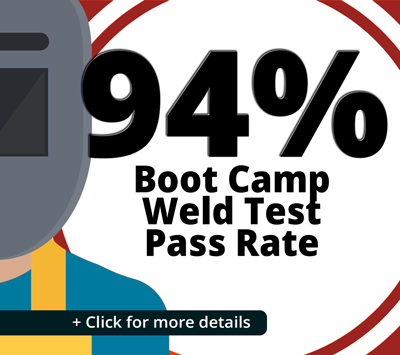

- Our Welding Boot Camp has a 94% pass rate and is designed to get those with various welding skills up to speed and up to Boilermaker standards.

Why Boilermakers?

Boilermakers do it all—but better. And that means Boilermakers save owners and contractors time and money. We're adaptable, experienced craftspeople who have multifaceted skillsets and can weld anything, no matter how tight the space or how dirty the project; build even the most uniquely complicated scaffolding; and rig any kind of load. Any kind.

Boilermakers complete the most challenging jobs on time, on budget and with safety as the priority of every project. Plus, the Boilermakers' unique crew distribution makes it possible to offer contractors and owners a flexible, tailored and ready workforce.

If you want skilled craftspeople who can complete any job with excellence, hire the Boilermakers. We'll stake our 130-year reputation on doing the job right. The first time.

What Owners and Contractors say about Boilermakers

-

“ Your membership continually demonstrates a commitment for excellence. [Boilermakers] again gave above and beyond effort to return our units 6 and 7 from a forced outage in safe and record time. I commend you. The Boilermakers working our massive AQC project also demonstrate this commitment for excellence.

— Frank A. Lubich, FirstEnergy

W.H. Sammis Plant

Scranton, Ohio -

Phillips 66 Wood River Refinery: Boilermaker productivity and quality

Refinery Safety Scheduling Budget Quality“ The craft performance on this job was a testament to the Boilermaker MOST Program and the cooperation among trades on the site, working under the GPPMA agreement.

— Madison Project Manager Robert Henderson

Full Article -

“The support of your staff in recruiting Boilermakers to support our outage work was excellent, and the support shown by the members of Local 60 to execute our outage commitments was exemplary. We especially appreciate the compliance to our safety program, which helped us achieve an outage without an OSHA recordable incident.

Again, our thanks go to you (Ed Hebert, L-60 BM-ST), your staff, and your members who supported us.— Venture Management team at Byron Nuclear Station: Project Manager Bob Vivian; Jacci Schlosser, work control support; and Fred Talsma, project support.

-

CB&I Stone & Webster Construction, Entergy Nuclear at Palisades Station: Excellent Boilermaker work

Nuclear Scheduling Quality“Recently Stone & Webster was called upon by our client, Entergy Nuclear, to assist in the replacement of the control rod drive housings on the reactor head at the Palisades Nuclear Station near Covert, Michigan. The added work was expected to extend the critical path of the Palisades refueling outage by approximately 28 days.

We were in need of highly skilled mechanics who could make the repairs correctly the first time. Local 169 was able to assemble the right team of Boilermakers and referred them to us in time to support the client's schedule. We are pleased to report that the repair work was completed approximately seven days ahead of the initial schedule. In fact, performance among the entire Boilermaker team at Palisades Station was excellent. Safety, quality, and productivity performance objectives were fully achieved.— Site Manager Rick Tinkle, Palisades Station, CB&I Stone & Webster Construction, Inc.

-

“ Members of Local 60 along with other building trades working under the supervision of Power Maintenance and Constructors LLC, successfully completed the spring outage on Unit 6 at the Havana Energy Complex owned and operated by Dynegy Coal. The outage work consisted of numerous projects including air heater seal refurbishments, SCR catalyst replacement, high-energy piping inspections, and miscellaneous boiler tube inspections and repairs. This work was completed ahead of schedule, under budget and with safety at the forefront. The tripartite approach, with input and interaction among the owner, contractor, and union labor, was essential in the overall success of these projects.

— Director of Operations Jeremy T. McKinney, P.E.

-

“ We have worked on seven of the nine units here at KIF this outage season with what is currently 1,645 days without a recordable injury, and in addition to this, we have managed to meet the expectations of some very aggressive outage scheduling. I personally recognize this . . . as one of the more successful outage seasons here at KIF in quite some time. We are looking forward to future outages with confidence, knowing that this is the safety culture and work ethic that we can expect from the members of Local 454.

— Clay Tipton, GUBMK

-

“ This low NOx burner and OFA retrofit was engineered by our client, Hitachi Power Systems North America. This was an extremely fast-track project. The challenges that were presented were overcome by the onsite team, allowing NAES PC to complete the project two days ahead of schedule. Safety was never compromised on this project, despite the adversity of the schedule.

— Regional Manager Russ Bright, NAES Power Contractors

-

Nine Mile Nuclear Generating Station, Scriba, New York: Finished ahead of schedule

Nuclear Scheduling Safety“ I want to personally thank you and your team for the excellent support you provided to my team this outage. I cannot tell you how impressed I am with the way you and your team worked safely and error free. This was the first time I did an outage utilizing Boilermakers and cannot be more happy with the results.

In reviewing our outage performance indicators, in addition to having zero first aids and one PCE, the disassembly and reassembly sections of the outage were both performed ahead of . . . schedule. Transitions were very well done as were look-aheads. I look forward to working with you next year on unit 2.— Sr. Manager William J. Pinkham, Reactor Services North East, Exelon Generation

-

“ The Boilermakers of L-85 demonstrated safe work habits and a professional attitude, and they provided a highly skilled workforce that allowed the Fremont Energy project to complete 68,744 man-hours without a recordable injury. A high degree of craftsmanship was also demonstrated when they performed over 150 ASME pressure-part circumferential butt welds on HRSG Boilers No. 1 and No. 2 with a . . . radiography rejection rate of [zero percent]. It was our pleasure to have the opportunity to work with exceptional craftsmen we sincerely appreciate the outstanding work of your members.

— Aker Construction President Steve Harker, Aker Construction VP Robert Hoover

-

“ I want to thank Boilermakers Local 29 for the outstanding safety performance your members have achieved on the Brayton Point Unit 3 Dry FGD/MRS project. As you may have heard, last month we were notified by OSHA that the project was awarded the VPP STAR Safety Award. This award is the most prestigious award bestowed by OSHA upon any business entity in our industry and it is something that we are extremely proud of. On behalf of Kiewit and Dominion, please express to your members our gratitude for the exemplary safety performance that has been achieved this year on the Brayton Point Project.

— Project Manager Chris Turnbull, Kiewit Infrastructure Co.

Full Article -

“ Back when this project was being scoped and planned, it was going to be a major construction challenge. And the Boilermakers were going to be a critical partner in executing the work within the schedule constraints allowed. I'm pleased to tell you today, the Boilermakers rose to the challenge and executed their work in impressive fashion. Many people doubted this job could be “pulled off” in the outage duration allowed. Many others couldn't envision how to even do the job at all. Well, it was done and done well. Through the use of an extensive temporary monorail system (consisting of 60 tons of temporary steel and a “jungle” of air chain hoists), 64 duct segments (300 tons total) were removed and 72 duct segments (400 tons total) were erected without incident. Over 10,000 linear feet of seam welding was executed on the new duct installation with only minor “pick ups” required. The Boilermakers’ work was completed three days ahead of our baseline schedule completion date for releasing the gas path to station operations.

— Robert Segiet, Project Manager, Hayes Mechanical-Site Construction Manager

-

“ I am writing this letter to commend and thank the members of Local 627 who worked on the Cholla Unit 1 horizontal superheat project in Joseph City, Arizona. “The Boilermakers removed and replaced 384 superheat assemblies and made 1,600 welds in 26 days. We x-rayed 240 welds, with no rejects. They managed to do this with wind delays, crane breakdowns and other obstacles. ASP (Arizona Public Service, owner/operator was very pleased with this outage. The project was completed with an excellent safety record and ahead of schedule.

— Site Manager William Lofthouse, Day & Zimmermann, Cholla Power Plant

-

“ There wasn't a single challenge presented to the Boilermakers that they didn't knock out of the park. Pride in themselves and their local, paired with their skill, really drove their success.

— Kiewit Project Safety Manager Tobe Schmidt

Read Article -

Bechtel Power, Ivanpah Solar Electric Generating System: Quality despite challenges

Renewables Quality“ If you think about the challenges that we've done here, we've met them all. And we certainly couldn't have done it without the Boilermakers that we've had here. It's the quality of the Boilermakers we've got here. I've told this to many people. I've been with Bechtel almost 30 years and I have to say that this is the best team that I've ever worked with.

— Site Manager, Bechtel Power Corporation, Fred Fine

-

Honua Ola Bioenergy retrofit in Hawaii: Excellence in an unpredictable environment

Bio-Mass Quality Safety Scheduling“ With the volcano erupting and lava flowing, it's a completely whole new world out here… The Boilermakers come out here and do something that they have been trained through an apprenticeship to do, and they can do it safely, with high amounts of quality in the time we're looking for.

— Site Manager for AZCO Construction, Inc., Paul Vogels

-

“ The Boilermakers performance and expertise on these jobs is more critical than ever…One thing I can always count on with Boilermakers Is that solid work ethic of ‘We're coming to work to get a job done and get it done professionally, with good quality and, most importantly, nobody getting hurt.’

— Project Manager for Kiewit Power, Billy Ours